|

Custom Design

Concept to Production in 4 Weeks

We use our design and engineering expertise along

with our state-of-the-art equipment to take a project from concept to production

in as little as four weeks

|

Paper Design

The design process begins with a detailed review of our

client’s specifications

to ensure that we have a clear and accurate understanding of their requirements. |

|

|

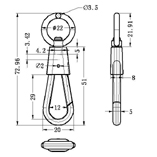

3d Digital Images

We then generate and present 3D photo-real images in a digital file using

SolidWorks CAD software. By giving our clients

a variety of 3D views, we assist

them in better visualizing the design to make sure that it conforms to their

requirements.

|

|

|

Plastic Prototype

When the design is complete, our rapid prototyping system will

use the digital file to create a plastic

3D model of the part within hours. Except for moving parts, it is a replication

of the actual piece that will be produced. The client can use this prototype to conduct a high-level review.

|

|

|

Metal Prototype

Once the 3D part is approved, we make a prototype in metal from the

digital file using

a 5-axis CNC milling machines. This is an exact representation of the final part.

|

|

|

Production Part

After the prototype is approved, we produce molds

or dies directly from the same digital file, ensuring that the production parts will match the

final metal prototype.

|

|

Please also see our Materials and

Finishes pages. |

|